GCK low-voltage withdrawable switch cabinet

use

GCK low-voltage withdrawable switchgear is widely used in power plants, metallurgical steel rolling, petrochemical industry, light industry and textile, ports, buildings and hotels and other places as AC three-phase four-wire or five-wire system, voltage 380V, 660V, frequency 50Hz, rated current 5000A and below power distribution and motor centralized control.

GCK is a comprehensive type test and CCC certification. It is an assembled high-level low-voltage switchgear designed to meet the following standards:

National Standard GB7251.1-2005 Low Voltage Switchgear

International Standard IEC60439.1-1992 Low-Voltage Switchgear and Control Equipment

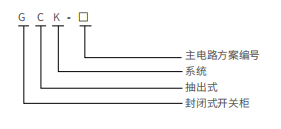

Model Meaning

normal conditions of use

♦ The ambient air temperature is not higher than +40°C and not lower than-5C, and the average temperature within 24 hours is not higher than +35°C;

♦ The relative temperature shall not exceed 50% at the highest temperature of +40 ° c, and a higher relative temperature shall be allowed at a lower temperature, such as 90% at + 2CTC;

Clean air, no corrosive and explosive gases, no conductive and insulating dust:

♦ No significant shaking and shock vibration occasions, vertical installation, inclination should not be greater than 5 degrees;

♦ The altitude does not exceed 2000 meters;

♦Switch cabinets are suitable for transportation and storage at the following temperatures:-2 5C to + 55C, not exceeding + 70C in a short period of time (not exceeding 24 hours);

The user shall negotiate with the manufacturer when the above conditions are not met.

.

Main technical parameters

♦ Rated insulation voltage 660V/1000V

♦ Rated working voltage 400V/660V

Rated working voltage of auxiliary circuit: AC 380V,220V, DC 110V. 220V

busbar rated current: 1000A, 1250A, 1600A, 2000A, 2500A, 3200A, 4000A, 5000A

Rated short-time withstand current of busbar: 50kA, 80kA (effective value) 1 second

busbar: 105kA/0.1Ss 140kA/0.1Ss 176kA/0.1s

Branch busbar rated current: 630A, 1000A, 1250A, 1600A

Branch busbar rated short-time withstand current: 30kA, 50kA (effective value) 1 second

Rated peak withstand current of branch bus: 63kA. 105kA/0.1s

♦ Enclosure protection grade: IP30, IP40

Busbar setting: three-phase four-wire system, three-phase five-wire system

Operation mode: local, remote, automatic

switch cabinet

power receiving cabinet bus contact cabinet feeder cabinet motor control cabinet power switching cabinet power factor compensation cabinet

structural features

GCK is a combined assembly structure. All structural parts of the cabinet frame are galvanized and sprayed with plastic, and are connected to each other by screw fastening to form a basic cabinet frame. Parts such as doors, baffles, partitions, drawers, mounting brackets, bus bars and electrical components are added as required to assemble a complete control center cabinet. The cabinet structure has the following characteristics:

Cabinet rack

cabinet frame is assembled with C profile, and the cabinet frame parts and special supporting parts are supplied by our company to ensure the accuracy and quality of the cabinet body.

& loz; The molding size, opening size and equipment interval of parts shall be modularized (modulus E = 20mm, the same below).

& loz; Internal structural parts are galvanized.

& loz; The top cover of the cabinet is removable, and the four corners of the cabinet top are equipped with lifting rings for lifting and shipping.

& loz; The cabinet frame is divided into three mutually isolated sections: bus room, functional unit room and cable room, which can prevent the spread of accidents.

Functional unit (drawer part)

& loz; The drawer unit has a height modulus of 200mm and is divided into five size series: 1/2 unit, 1 unit, 1.5 unit, 2 unit'3 unit. Unit circuit rated current 630 A and below.

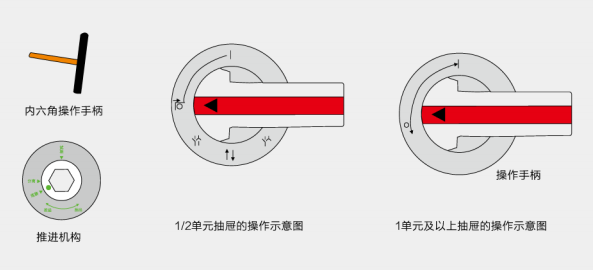

(see the figure above).

& loz; Each MCC cabinet can be equipped with up to 9 1-unit drawers or 18 1/2-unit drawers.

& loz; The operating mechanism is mechanically interlocked with the drawer. When the main switch is in the closing position, the drawer cannot be pulled out.

& loz; The operating mechanism of the drawer can be locked in the closing or opening position with a padlock, which can safely carry out maintenance of electrical equipment o

& loz; The back of the functional unit has a main circuit inlet and outlet plug and an auxiliary circuit secondary plug.

& loz; The functional unit compartments are separated by metal partitions.

& loz; The drawer unit adopts rotary propulsion mechanism, with three-position function, simple and reliable operation.

& loz; The GCK drawer advancing mechanism adopts the movement mode of spiral track along the positioning part to realize the advancing and withdrawing of the functional unit. During the advancing and withdrawing of the functional unit, it realizes three-position display and mechanical interlocking and is equipped with micro switch. Electrical interlocking can be carried out in the test position.

Installation and Use

After the product arrives at the place of receipt, it shall first check whether the packaging is intact, and if any problem is found, it shall promptly notify the relevant departments of the contract to make business records, jointly analyze the reasons for the visa, and deal with the aftermath.

For products that are not installed immediately, they should be placed in an appropriate place and kept properly in accordance with normal use conditions and temporary storage procedures for electrical equipment.

The installation of the product shall be carried out according to the installation diagram. The foundation channel steel and the bolts fixed by bolts shall be provided by the user. When the main bus is connected, if the surface is uneven due to transportation, storage and other reasons, it shall be leveled and then connected and tightened.

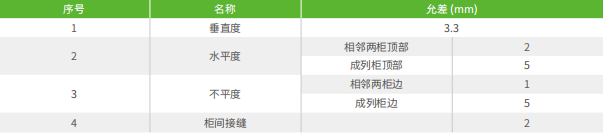

When the equipment is installed separately or in columns, its verticality, unevenness of cabinet surface and deviation of gap between cabinets shall meet the requirements of Table 1..

Inspection and test of products after installation and before operation.

& loz; Check whether the top paint or other covering materials (such as plastic spray) of the cabinet are damaged, whether the cabinet is dry and clean, and whether the mounting screws of each part are loose.

& loz; Whether the operating mechanism of electrical components is flexible, and there should be no sticking or excessive operating force.

& loz; Whether the on-off of the main electrical appliances is reliable and accurate.

& loz; Drawer or withdrawal mechanism shall be flexible, light and free from jamming and collision.

& loz; The center lines of the moving and static contacts of the drawer or extraction structure shall be consistent, and the contacts shall be in tight contact. The insertion depth of the main and auxiliary contacts shall meet the requirements. The mechanical interlocking or electrical interlocking device shall act correctly, and shall be reliably locked or released.

& loz; Drawers with the same primary scheme, secondary principle and drawer size shall be easily interchangeable without jamming and collision.

& loz; When replacing the fuse core, it should meet the requirements of engineering design.

& loz; The setting value of protection should be set correctly according to the actual load.

& loz; The insulation resistance value measured with a 1000V megohmmeter shall not be less than 10M Q.

& loz; The connection of each bus shall be good, and the insulation support, installation parts and other accessories shall be installed firmly and reliably.

Notice of Use

& loz; The equipment is a low-voltage distribution cabinet that is not installed against the wall, is operated on the front and is maintained on both sides. The maintenance channel and door of the cabinet must be entered or opened by qualified professionals for operation, inspection and maintenance.

& loz; After connecting the cable, the bottom of the switch cabinet should be closed to prevent small animals from climbing into the cabinet and causing short circuit accidents.

& loz; After many times of separation and closing, especially after short-circuit separation and closing, air circuit breakers and molded case circuit breakers will cause local burns of contacts and produce carbon substances, which will increase the contact resistance. Maintenance and overhaul shall be carried out according to the operation instructions of the circuit breaker.

& loz; After installation and maintenance, the isolation between compartments and functional units must be strictly checked to ensure good functional separation of the device and prevent the expansion of faults.

♦ Drawer operation

& loz; 1/2 unit drawer operation

The operating mechanism of the drawer is composed of a rotating part, a rotating shaft, a lock, etc., and has the functions of opening and closing, testing, isolation and locking of the switch. The operating mechanism is also equipped with a microswitch for electrical latching purposes.

I working position: the main switch is closed, the main circuit and control circuit are connected, and the function unit is locked. (O) Opening position: the main switch is opened, the control circuit is connected, and the function unit is locked.

Test position: the main switch is opened, the main circuit is disconnected, the control circuit is connected, and the function unit is locked.

isolation position: drawer 30mm. The main and control circuits are isolated and disconnected, and the drawer is locked.

Withdrawal position: both the main circuit and the control circuit are disconnected, and the drawer can be withdrawn at will.

After the operating handle is pressed down by 6mm, it can turn from (O) position to (1) position.

working process: in the extracted position (I. e.), the drawer can be pushed or pulled out, and after rotating 45 degrees counterclockwise, the drawer can automatically reach the isolation position (park) when pulled out. Rotate 45 ° clockwise to reach the test position (U)o Rotate 45 ° clockwise to reach the switch breaking position (0). Press down the handle by 6mm and turn it 90 ° clockwise, then switch on the switch. If you need to exit, operate in reverse order. If necessary, padlocks can be added to the operating handle at the three positions of main switch opening, test and isolation as safety protection.

& loz; unit and above drawer

test: the main switch is opened, the main circuit is disconnected, the control circuit is connected, and the function unit is locked. Separation: the main switch is opened, the main circuit is disconnected, the control circuit is disconnected, and the drawer is drawn out at will. Connection: the main circuit plug-in, the control circuit plug-in can be switched on and off, and the functional unit is locked. I: Circuit breaker closing; O: Circuit breaker opening.

operating instructions: adjust the drawer pushing mechanism to the "separation" position, rotate clockwise with the "hexagon socket operating handle" to the "connection" position, rotate the operating handle clockwise by 90 °, and close the circuit breaker; the opening operation sequence is opposite to the above.

Note: 1. The circuit breaker cannot be closed when the propulsion mechanism is in the test position and the separation position.

2. The push mechanism cannot be operated when the switch is in the closing position.

♦ Unlocking mechanism

There is a round hole in the lower right corner of the drawer of Unit 1 and above, which is the unlocking mechanism of the drawer door. When the drawer pushing mechanism is in the connection position and the switch handle is in the "0" position, pull out the small cover first, insert a small screwdriver into the hole and move the lock catch downward to open the door. After closing the door, the plastic small cover must be covered, otherwise the original protection level will be damaged.

Factory data and accessories

manufacturer shall provide the following documents and attachments when supplying

Shipping List Product Certificate and Factory Test Report

Instructions for use Relevant electrical drawings

Main component specification Cabinet door key, operating handle and spare parts specified in the contract.

Ordering Instructions

, the user shall provide:

Main circuit distribution system diagram and layout plan, rated working voltage, rated working current, setting current of protection device and necessary technical parameters.

♦ Indicate the specifications of incoming and outgoing cables.

The model, specification and quantity of the main electrical components in the switch cabinet.

If busbar bridge or busbar duct is required between switch cabinets or incoming cabinets, specific requirement data such as span and height from the ground shall be indicated.

When the switch cabinet is used in special environmental conditions, it should be specified in detail when ordering.

Surface color of switch cabinet and other specific requirements.

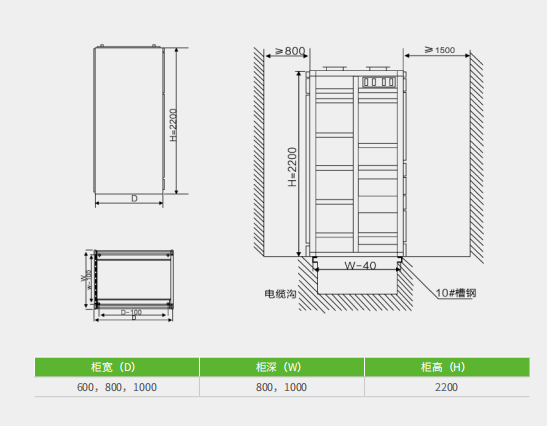

Dimensions and Installation

See the following table for external dimensions

GCK series switch cabinet is not installed vertically against the wall, and its rear is the outlet cable trench of the cabinet body. For convenience of maintenance, the rear is usually 800-1200mm from the wall, and the front distance is shown in the following figure.

![[15]GCK 低压抽出式开关柜-低压开关柜系列-光伏并网柜_光伏箱变_固体绝缘环网柜_充气柜-众用电气 [15]GCK 低压抽出式开关柜-低压开关柜系列-光伏并网柜_光伏箱变_固体绝缘环网柜_充气柜-众用电气](http://nwzimg.wezhan.net/contents/sitefiles3607/18037698/images/7872675.png)

![[15]GCK 低压抽出式开关柜-低压开关柜系列-光伏并网柜_光伏箱变_固体绝缘环网柜_充气柜-众用电气 [15]GCK 低压抽出式开关柜-低压开关柜系列-光伏并网柜_光伏箱变_固体绝缘环网柜_充气柜-众用电气](http://nwzimg.wezhan.net/contents/sitefiles3607/18037698/images/7872675.png?x-oss-process=image/resize,m_lfit,h_200,w_200)