GGD low-voltage switchgear

Main Circuit Scheme

the main circuit of the GGD cabinet, 129 schemes are designed, with a total of 298 specifications (excluding the schemes and specifications derived from the functional changes of the auxiliary circuit and the changes of the control voltage). Among them: GGD1 49 schemes 123 specifications

GGD2 53 schemes 107 specifications

GGD3 type 27 programs 68 specifications

is selected after consulting the opinions of the majority of design and use departments, and the scheme required by the power plant is added. The rated current is increased to 3200A, which is suitable for distribution transformers of 2000kVA and below. In addition, in order to meet the needs of reactive power compensation, the GGJ1-GGJ2 capacitor compensation cabinet is designed, and its main circuit has 4 schemes, a total of 12 specifications.

Auxiliary Circuit Scheme

auxiliary circuit is divided into two parts: power supply scheme and power plant scheme. There is enough space to install secondary components in GGD cabinet.

Selection of Electrical Components

& loz;GGD cabinet mainly adopts more advanced electrical components that can be mass-produced in China, such as me, dw15. Dw17.DW45, CM1, NM1, etc. At the same time, according to the principle of economy and rationality, some available old products such as DZ20 are retained under the premise of full consideration of feasibility. Do not use obsolete products.

& loz;HD13BX and HS13BX type rotary operation knife switch to meet the needs of the unique structure of the GGD cabinet design of special components, it changed the mechanism of operation, retain the advantages of the old products, is a kind of utility model of electrical components.

& loz; If the design department selects new electrical components with better performance and more advanced technology according to the needs of users, the GGD cabinet will generally not cause difficulties in manufacturing and installation due to the good installation flexibility of the GGD cabinet.

& loz; In order to further improve the dynamic stability of the main circuit, the ZMJ type combined bus bar clamp and insulating support for GGD cabinet are used. The bus bar clamp is made of high strength, high flame retardant PPO alloy material thermoplastic molding, high insulation strength, good self-extinguishing performance, unique structure, only need to adjust the building block can be easily combined into a single bus bar clamp or double bus bar clamp, insulation support sleeve type molding structure, low cost, high strength, to solve the old product creepage distance is not enough defects.

Structure Introduction

The cabinet body of GGD AC low-voltage power distribution cabinet adopts the type of general cabinet. The frame is partially welded and assembled with 8MF cold-formed steel. The frame parts and special matching parts are supplied by the fixed-point steel production plant to ensure the accuracy and quality of the cabinet body.

general cabinet are designed according to the module principle and have 20-die mounting holes. The high general coefficient can make the factory realize pre-production, which not only shortens the production cycle, but also improves the work efficiency.

♦ggd cabinet design fully takes into account the heat dissipation problem during cabinet operation. There are different numbers of heat dissipation slot holes at the upper and lower ends of the cabinet body. When the electrical components in the cabinet generate heat, the heat rises and is discharged through the upper slot hole, while cold air is continuously added into the cabinet through the lower slot hole, so that the sealed cabinet body forms a natural air duct from bottom to top to achieve the purpose of heat dissipation.

♦ggd cabinet adopts the method of golden section ratio to design the exterior shape of the cabinet and the division size of each part in accordance with the requirements of modern industrial product modeling design, so that the whole cabinet is beautiful and elegant and has a new look.

The cabinet door is connected with the frame by rotating shaft movable dumpling chain, which is convenient to install and disassemble. A mountain-shaped rubber strip is embedded at the folding edge of the door. When closing the door, the molding between the door and the frame has a certain compression stroke, which can prevent the door from directly colliding with the cabinet body and improve the protection level of the door.

The instrument door equipped with electrical components is connected with the frame by multi-strand soft copper wire, the installation parts in the cabinet are connected with the cabinet frame by knurled screws, and the whole cabinet forms a complete grounding protection circuit.

The surface of the cabinet is sprayed with plastic, with strong adhesion and good texture. The whole cabinet is matte, avoiding dazzling effect and creating a more comfortable visual environment for the personnel on duty.

The top cover of the cabinet body can be removed when necessary to facilitate the assembly and adjustment of the main bus on site. The four corners of the cabinet top are equipped with lifting rings for lifting and shipping.

♦The protection level of the cabinet is IP30, and users can also choose between IP20 ~ IP40 according to the requirements of the use environment.

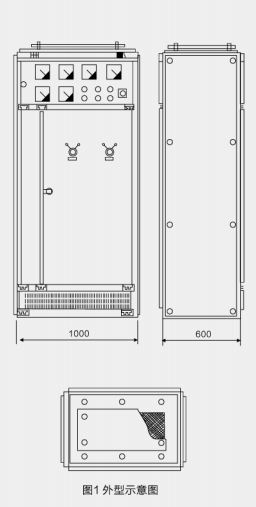

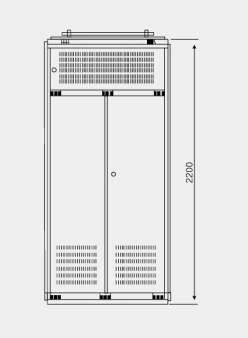

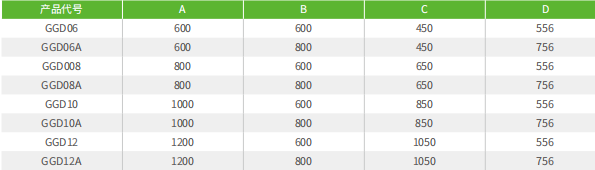

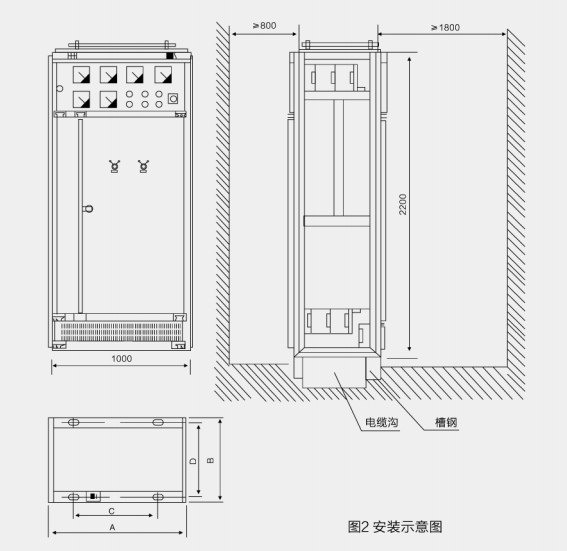

appearance and installation dimensions.

Installation and Use

After the product arrives at the receiving place, it should first check whether the packaging is intact, and notify the relevant departments to find out the reason in time. For products that are not installed immediately, they should be placed in an appropriate place according to the normal conditions of use.

♦ Product Installation

products shall be carried out according to the installation schematic diagram (see Figure 2). The foundation channel steel and bolts shall be provided by the user. During the installation of the main bus, the overlapping surface shall be repaired and cleaned, and neutral vaseline or other measures shall be applied, and then the bolts shall be fastened.

After the product is installed and put into operation, the following items shall be checked and tested o

& loz; Check whether the top coat of the cabinet falls off and whether the cabinet is dry and clean.

O electrical components is flexible, and there should be no sticking or excessive operating force.

& loz; Whether the on-off of main electrical components is reliable and accurate, and whether the on-off of auxiliary contacts is reliable and accurate.

& loz; Whether the ratio and polarity of instrument indication and transformer are correct.

& loz; Whether the bus connection is good, and whether the insulating support, installation parts and accessories are installed firmly and reliably. & loz; Whether the auxiliary contact meets the requirements, whether the fuse core specification of the fuse is correct, whether the setting value of the relay meets the design requirements, and whether the action is accurate.

& loz; Whether the contacts of the circuit meet the requirements of the electrical schematic diagram.

& loz; whether the protection circuit system meets the requirements.

& loz; insulation resistance shall not be less than 10 megohms as measured with a 500 volt megohmmeter.

Notice of Use

& loz; This product is not installed against the wall, single-sided (front) operation, double-sided door maintenance of low-voltage power distribution cabinet. The maintenance channel and cabinet door of the product must be entered or opened by qualified professionals for operation, inspection and maintenance.

& loz; After many times of closing and dividing, the air circuit breaker will locally burn the main contact and produce carbon substances, thus increasing the contact resistance. The air circuit breaker should be regularly maintained and overhauled according to its operating instructions.

& loz; The isolating switch is not allowed to open and close under load.

Factory data and accessories

manufacturer shall provide the following documents and attachments when supplying

♦ Shipping List

Product certificate and factory test report

♦Instructions for use

Relevant electrical drawings

Main Component Instruction

Cabinet door keys, operating handles and spare parts specified in the contract.

Ordering Instructions

, the user shall provide:

Main circuit distribution system diagram and layout plan, rated working voltage, rated working current, setting current of protection device and necessary technical parameters.

♦ Indicate the specifications of incoming and outgoing cables.

The model, specification and quantity of the main electrical components in the switch cabinet.

If busbar bridge or busbar duct is required between switch cabinets or incoming cabinets, specific requirement data such as span and height from the ground shall be indicated.

When the switch cabinet is used in special environmental conditions, it should be specified in detail when ordering O

Surface color of switch cabinet and other specific requirements.

appearance and installation dimensions

![[15]GGD 低压成套开关柜-低压开关柜系列-光伏并网柜_光伏箱变_固体绝缘环网柜_充气柜-众用电气 [15]GGD 低压成套开关柜-低压开关柜系列-光伏并网柜_光伏箱变_固体绝缘环网柜_充气柜-众用电气](http://nwzimg.wezhan.net/contents/sitefiles3607/18037698/images/7872732.png)

![[15]GGD 低压成套开关柜-低压开关柜系列-光伏并网柜_光伏箱变_固体绝缘环网柜_充气柜-众用电气 [15]GGD 低压成套开关柜-低压开关柜系列-光伏并网柜_光伏箱变_固体绝缘环网柜_充气柜-众用电气](http://nwzimg.wezhan.net/contents/sitefiles3607/18037698/images/7872732.png?x-oss-process=image/resize,m_lfit,h_200,w_200)