Phase:Three

Core:Core-type Transformer

Three Phase Cast Resin Dry Type Transformer 800-25000KVA/10-34.5KV Tailored design Accessoies

Basic Info.

| Model NO. | 1600-11/0.4 | Cooling Method | Dry-type Transformer |

| Winding Type | Two-winding Transformer | Certification | ISO9001-2000, ISO9001, CCC, KEMA Dekra ASTA Marine CE |

| Usage | Rectifier Transformer, Power Transformer, Distribution Transformer, Cast Resin Transformer | Frequency Characteristics | Low Frequency |

| Shape of Core | U | Production Capacity | Pearl Electric |

| Type | Dry Type Cast Resin Transformers | Reference Standards | IEC60076 |

| Capacity | 1600 kVA or Customized | Rated H. V. | 11kV or Customized |

| Rated L. V. | 0.4kV or Customized | Impedance | 4~8% or Customized |

| Cooling Way | AN/AF | Winding | Cooper/Aluminum |

| Core Material | Silicon Steel | Insulation Level | as Per IEC Standard |

| Vector Group | Dyn11 or Customized | Insulation Class | H-Class or Customized |

| Temperature Rise | 125K | Enclosure | IP20-IP54 |

| Accessories | Enclosure/Monitoring Unit/Temperature Control | Transport Package | Wooden Pallet |

| Specification | Up to 25MVA | Origin | China |

| HS Code | 8504340000 |

Packaging & Delivery

| Package Size | 1.00cm * 1.00cm * 1.00cm |

| Package Gross Weight | 1.000kg |

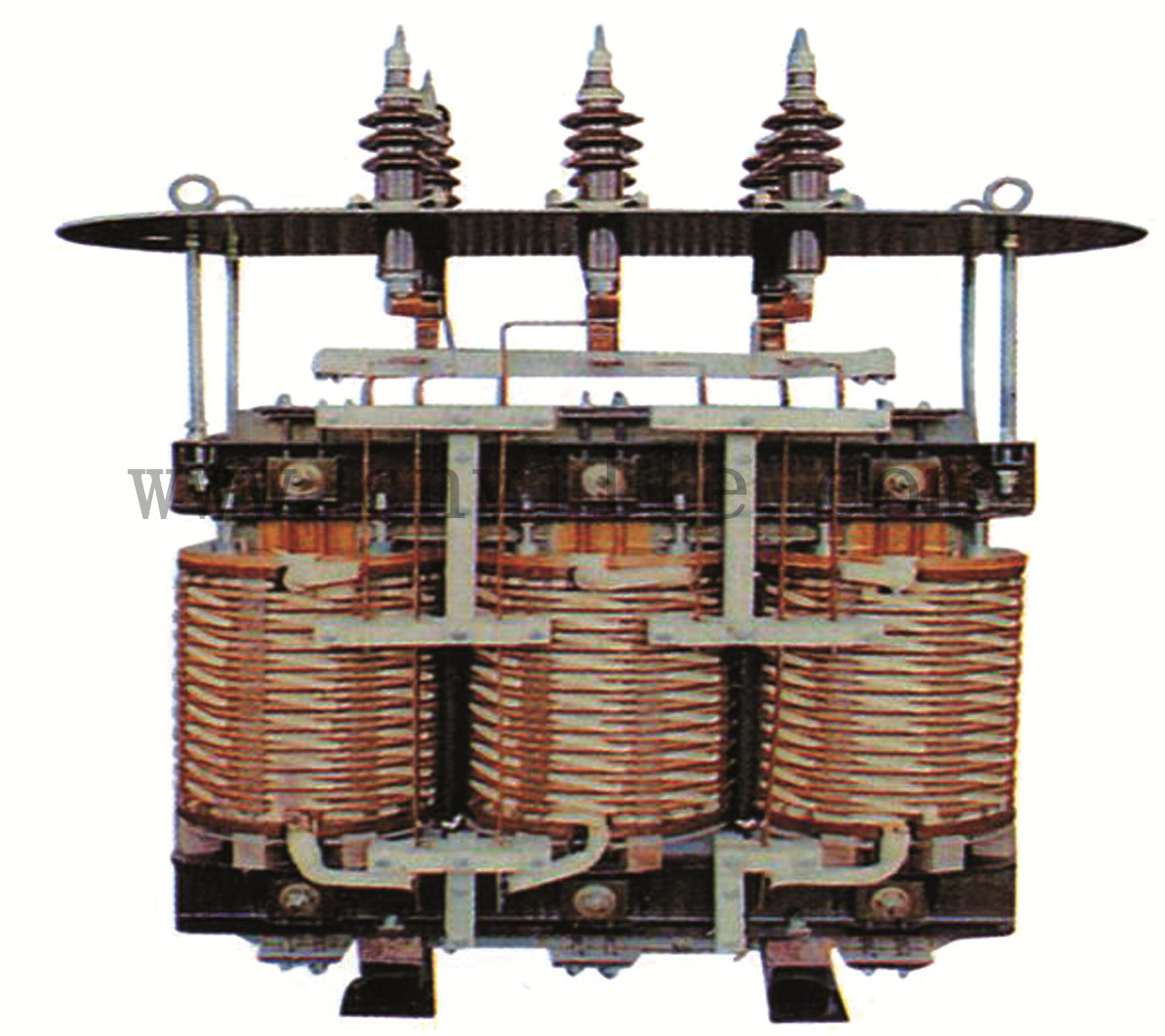

Product Display

| 01 | Production Descriptions | Cast Resin/Dry type Power Transformer | |||

| 02 | Reference standards | IEC 60076 | |||

| 03 | Capacity | 1600kVA | |||

| 04 | Voltage (HV) | 11kV | |||

| 05 | Voltage (LV) | 0.4kV | |||

| 06 | Applied in | Wind Turbines | |||

| 07 | Impedance % | 4~8% | |||

| 08 | Connections (Vector Group) | Dyn11 | |||

| 09 | Frequency | 50Hz/60Hz | |||

| 10 | Tapping Range | ±2×2.5%, NLTC/OLTC | |||

| 11 | Core materials | Silicon Steel | |||

| 12 | Winding materials | Copper | |||

| 13 | Noise Level (dBA) | As per IEC Specifications | |||

| 14 | Cooling method | AN/AF | |||

| 15 | Optional Accessories | Temperature sensor | |||

| 16 | Temperature control | ||||

| 17 | Cooling fans | ||||

| 18 | Skid-type underbase | ||||

| 19 | Transformer wheels | ||||

| 20 | Current transformer | ||||

| 21 | Protective Enclosure(IP20-54) | ||||

Product Advantage

Low Loss: Our transformers are designed for maximum efficiency, reducing energy consumption and operating costs.

Low Noise: Advanced noise reduction technology ensures our transformers operate quietly, creating a more comfortable environment for users.

Low Partial Discharge: Our transformers exhibit low partial discharge levels, enhancing their electrical insulation performance and extending their lifespan.

High Reliability: Rigorous quality control and testing guarantee that our transformers perform reliably under various operating conditions.

Powerful Anti-Short Circuit Capacity: Our transformers are engineered to withstand short circuits, ensuring stable operation and safety.

High Anti-Lightning Impulse Capacity: The HV coils are vacuum-casted with epoxy resin under pressure, enhancing their resistance to lightning impulses and improving overall durability.

Advanced Simulation Analysis: We employ simulation analysis in the core model to avoid resonance and reduce noise, providing a quieter operation.

Enhanced Lightning Impulse Analysis: Simulation calculations and analysis of lightning impulse waves are applied to HV coils, improving their anti-lightning impulse capability.

Core:

- Our transformer's core is made of high quality cold rolled grain oriented silicon steel sheet with high magnetic permeability. It is using full 45° slope lamination, so that the no-load loss and the no-load current are reduced efficiently.

- We use Simulating Analysis in the core model design, so that we can calculate the frequency and size of the vibration exactly and avoid the core cavity resonance.

- Between core & windings, and core & frame, we use spring connection. Then the noise is lower 10 to 15dB than the standard.

LV Winding:

- LV windings, above 400 kVA capacity, are adopting superior foil conductors, thus to obtain better amper-turn balance and reduce more transverse magnetic flux leakage. Then to greatly improves transformer's anti-short circuit capability.

- The wise design of air passage within the winding, greatly increasing the winding's heat dispersion effect. It helps to decrease temperature rise and improve products' overload capability.

HV Winding:

- HV windings are made of superior copper-conductor wires. Adopting fiberglass to reinforced insulation.

- The HV windings are casting under vacuum and high pressure conditions with Germany HUBERS vacuum Cast Machine. In this way, transformer's resin can get the best penetration. It can also greatly reduce its partial discharge (partial discharge for 11kV product could be lower than 5pC).

- HV windings are adopted optimized structure to improve transformer's distribution of electric field.

- We use our existing technology calculate and analysis Lightning wave process simulation. Then substantially improving product's anti-lighting capability.